Quality

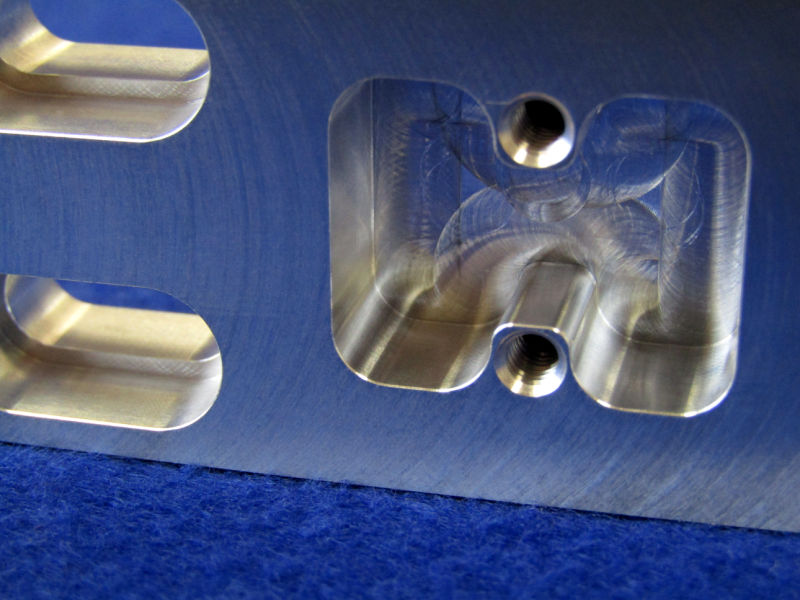

Bay Engineering are renowned for quality components.

We start with the basics, employing quality system BS EN ISO 9001:2015, but then add our own measures, to deliver the standards our customers expect:

- A high precision Aberlink Axiom too HS CNC Coordinate Measuring Machine (CMM).

- A dedicated Quality Engineer.

- A Baty R14 Touchscreen Profile Projector/Shadowgraph

- A meticulously equipped, clean and tidy CNC machine shop.

- Well organised office for processing and planning orders.

- A Quality and Safety Manager.

- Detailed production instructions that pass customer requests through every stage of a componnents manufacture.

- Detailed and easy to access information of material and sub contract processes purchased for your components.

- All information from previous batches, if the part is manufactured more than once, is instantly available.

- Regular internal audits of all processes used.

- Annual external audits.

- Highly skilled and trained staff.

Customer Certification

Certificates of Conformity are supplied free of charge on request. Mill Certificates and First Article Inspection Reports (FAIR) are also available for an additional fee.

Visit Us

We always welcome customer and potential customer visits, either for an informal look around or a more formal quality audit by your company.